Description

Alcohol Solvent Recycle and Recovery System

Alcohol Recovery System

Alcohol(or ethanol) has been used as a solvent in extraction equipment for a very long time and a large quantity of alcohol is consumed in the extraction industry. So it is very important to recycle and reuse to save production costs. And the truth is that it really saves to recovery alcohol solvent. Our alcohol solvent recovery tower can distill 30-50% used ethanol to 90~95%. We provide pharmaceutical industries with the recycling equipment. We can not only help to reduce waste, recycling solvents but to save production cost.

Alcohol Recovery Equipment Structure

Good solvent recycler uses fractional distillation by temperature and that has a well-designed distillation column. Theoretically, the higher the distillation column is, the higher the recycling rate is. But considering the alcohol distillation column manufacturing cost, we most suggest to get about 93-95%; Otherwise, the extra investment for recovery equipment will not bring back corresponding revenue. The solution is that a part of new pure alcohol is mixed up with the recycled one to be used again.

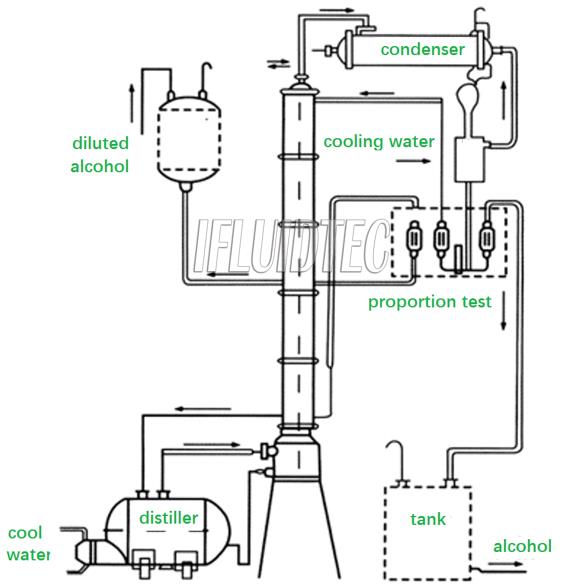

The working principle of alcohol recovery tower is that in most cases, alcohol is with a lower boiling point temperature than other ingredients in biomass. So by temperature higher than the alcohol boiling point, the diluted alcohol will evaporate. The alcohol vapor goes into the distilling column and condensate down into liquid again and be separated from others.

The alcohol recycle system is mainly composed of six parts: distill column, tower body, condenser, cooler, buffer tank, and high-level storage tank. It is suitable for the recovery of dilute alcohol in the pharmaceutical, food, chemical and other industries. The contact parts of the recycling system and materials are made of stainless steel 304 or 316L, which has good corrosion resistance And has the advantages of energy-saving, environmental protection, reducing production costs and improving efficiency. The device can distill 30-50 degrees of dilute alcohol to 93-95 degrees. The alcohol content of the residual liquid is low, which meets the requirements of environmental protection.

Alcohol Recovery Equipment Parameter

| Model | JH-200 | JH-300 | JH-400 | JH-500 | JH-600 | JH-800 |

| Tank Size(L) | 640 | 1220 | 1450 | 1450 | 2500 | 3200 |

| Tank Height(mm) | 6000 | 7000 | 7000 | 7000 | 7500 | 7500 |

| Condense area(m2) | 5 | 9 | 11.0 | 18 | 25 | 45 |

| Cooling area(m2) | 1 | 1.5 | 2.2 | 4 | 6 | 8 |

| Heating area(m2) | 3 | 6 | 6.5 | 10 | 15 | 26 |

| Recycle(Kg/h) | 40~50 | 90~100 | 280~300 | 420~440 | 600~620 | 720-820 |

| Recycle density(%) | >90 | |||||

| Padding | Stainless steel corrugated packing | |||||

| Dimension(m) | 2.3*0.7*9.3 | 2.6*0.8*12.5 | 2.5*1*15 | 3*1.2*18 | 3.5*1.4*18 | 4.2*1.8*18 |

Reviews

There are no reviews yet.