Description

Fermentation Tank

Bioreactor and Fermentation Tank

The bioreactor is an apparatus in which a biological reaction or process is carried out, there are small lab size and big industrial scale. A fermenter is an enclosed and sterilized vessel in which the microorganism growth takes place under controlled conditions like temperature, pressure and time. After fermentation to get large quantities of the desired metabolite for commercial use. There is no clear cut difference between the bioreactor and fermenter, they are more like the relation between ‘shoes and boots’. Or most of the fermenters can be classified into the bioreactor. The bio-fermentation tank can be used as batch cultivation and continuous fermentation. The former is mostly used in lab R&D while the latter is for industrial production. Since the fermentation vessel is of limited space, so for the ongoing cultivation process, the bioreactor will be designed to be able to release metabolic waste and refill nutrients to keep then microorganism growth always at the peak rate. The bioreactor and fermenter produced by our company are widely used in various bioprocess fields including pharmacy (insulin, monoclonal antibodies, vaccines, and blood products, cell culture), medicine, food, brewing, bio-fertilizer, and biological feed industry.

Bioreactor and Fermenter Design Concept and Overview

No matter big or small size of bioreactor and fermenter, they should have basic features. The below data is only for reference; parameter will be modified upon requirement.

1. Tank system

Manufacturing material: SS31603 or SS30408 stainless steel;

Inside Design pressure: 0.3MPa; jacket design pressure: 0.35MPa;

Fermenter Fittings: special sampling and discharge valve, temperature prober, PH sensor, DO sensor, foam prober, sight glass mirror port, feeding port, inoculation port, exhaust port; Surface Polish: stainless steel internal and external mirror polishing, polishing roughness≤ Ra0.4;

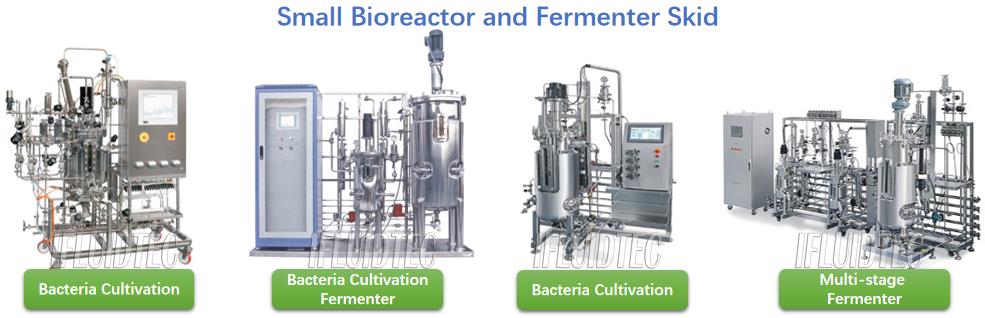

Fermentation Equipment for Biotechnology

We have small size bacterial/cell cultivation vessel with fermenter, secondary bio-fermenter and multi-stage fermentation vessel, fully customized and fully functioned on a skid, saving time for installation.

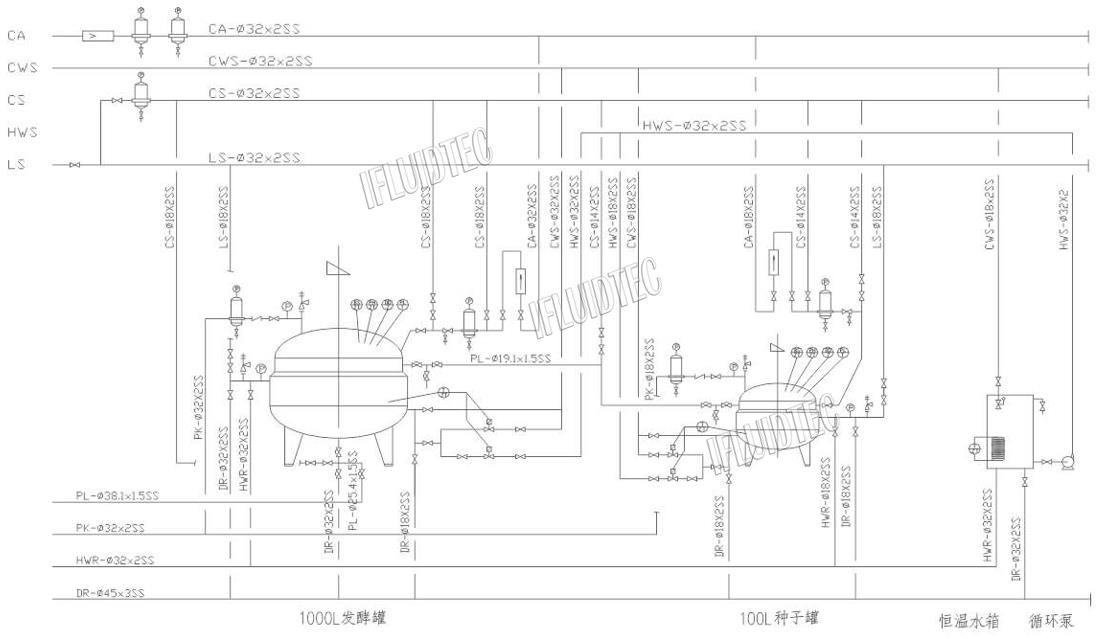

Stainless Steel Fermenter Design Structure(for learning and sample)

Industrial Big size Bioreactor& Fermentation Vessel

Fermentation Vessel Design Parameter

| Model | 100L | 200L | 500L | 1000L | 2000L | 5000L | 10000L | 20000L |

| DIA(mm) | 400 | 500 | 700 | 900 | 1200 | 1500 | 1800 | 2300 |

| HEIGHT(mm) | 2000 | 2300 | 2650 | 2900 | 3800 | 4480 | 5250 | 6550 |

| Stirring NO. | 1 | 1 | 2 | 3 | 3 | 4 | 4 | 4 |

| Rotate(r/min) | 20-300 | |||||||

| Power(Kw) | 0.55 | 0.75 | 1.1 | 1.5 | 3 | 5.5 | 7.5 | 7.5 |

| Jacket(MPa) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| In-Tank(MPa) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

Control System: (designed as asked)

Speed control: intelligent automatic PID control, variable stirring speed: 50-1000rpm, accuracy ±5‰;

DO control: PID intelligent automatic control, imported Swiss electrodes, and cables, measuring range: 0-150%; Accuracy:± 3%. Display range: 0.00 to 14.00 ± 0.01, control range: 2.00 to 12.00 ± 0.02;

Online detection, automatic alarm, the peristaltic pump add acid/alkali solutions automatically upon programmed;

Analysis report content: like PH value curve, acid/alkali volume curve, the cumulative amount of acid/alkali added, batch report; Temperature control: thermostatic bath + PT100 temperature sensor + electric heating + solenoid valve range; Cooling water temperature: 3~60 ℃;

Other Controls like Defoaming, Ventilation, Pressure, Sterilization be discussed.

Tags: stainless steel fermentation tank, laboratory fermenter, bioreactor, bio-fermentation vessel, yeast enzymes, and microorganisms fermenter, big fermentation equipment, beer fermentation tanks, fermentation pot, fermentation reactor, stainless steel fermenter, stainless steel conical fermenter.

What Can We Do?

We can send you offer specific inquiry and requirement; Prepare drawing after order confirmation; Double confirmation on drawing and strictly produce upon; Professional technology, complete specification and reasonable price; Our MOQ is 1 set; B2C or B2B, OEM is available. Confidentiality for our buyers. Users can buy fermentation systems as a project from or just order tanks and combinate other sensors, testers on their own. We can design or just manufacture upon drawing provided.

Industrial Biochemical Stainless Steel Conical Fermenter

Reviews

There are no reviews yet.