Description

Ethanol Extraction Machine|Lab R&D to Medium Size

Ethanol Extraction Machine Description

Small Ethanol Extraction Machine is suitable for medicine, health care products, bio-pharmaceuticals, cosmetics, food and other industries of ambient pressure extraction, ultrasonic extraction, essential oils, aromatic oils extraction, purification, and other processes. The herb extraction equipment is very suitable for universities, research institutes, laboratories, and pharmaceutical research and development departments of many varieties, small batch production use.

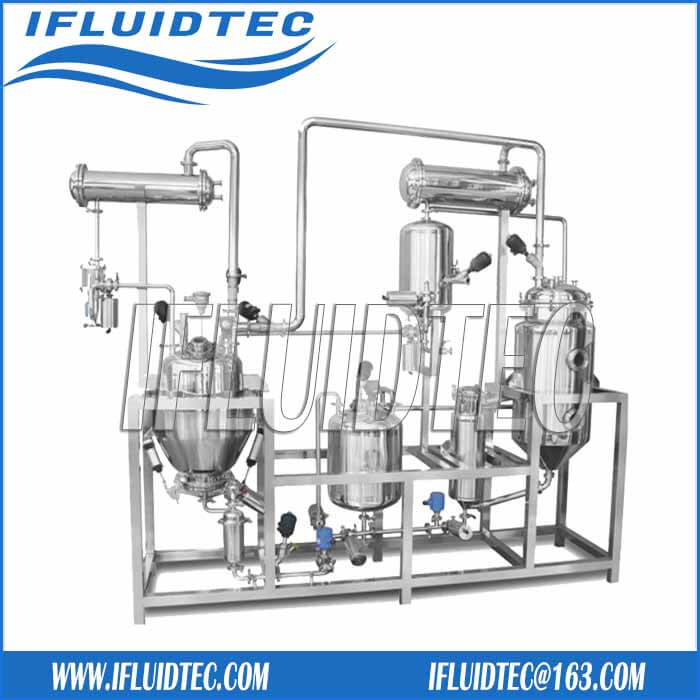

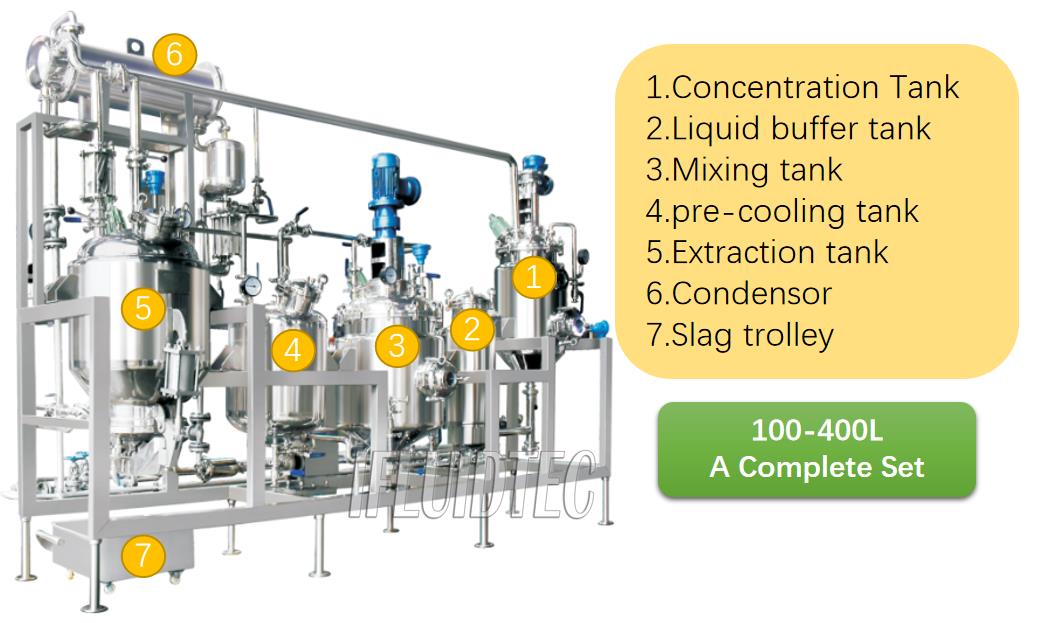

Lab Alcohol Extraction Machine Structure

Lab Alcohol Extraction Machine Components and Characteristics

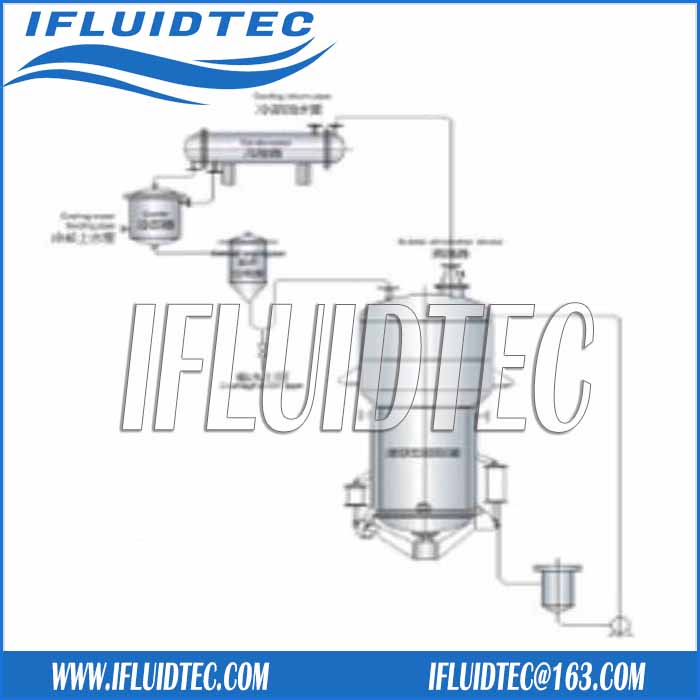

1. The plant oil extraction machine consists of an extraction tank, tube heater, evaporator, condenser, oil separator, oil receiver, liquid medicine pump, metering tank, liquid storage tank, filter, vacuum pump, power and control cabinet, etc. The extraction tank and the steam outlet of the evaporator are equipped with a de-bubble/de-foam device. Different processes and steps are combined into one complete system.

2. It can perform hot reflux circulation extraction and concentration; conventional extraction and concentration; water or alcohol as extracting solvent, percolation and other operations.

3. This herb extraction system can work under negative pressure, normal pressure and positive pressure. It can adapt to water extraction, alcohol extraction or other kinds of solvents extraction, and meets GMP requirements.

4. The unit has great advantages in terms of multi-function, high efficiency, energy-saving, and wide application range. In terms of comprehensive performance, it is domestically leading. It is pilot-scale extraction equipment for natural plants.

5. The overall manufacturing material is 304 stainless steel; the material contact part can be 304 or 316L optional.

6. All necessary parts of this extractor and evaporator are installed on a strong SUS frame, be fully inspected and tested before shipment; Very easy to install and ready to use when clients receive this set.

7. Since all components are compacted designed and placed on the frame, the operation space for this extraction machine is relatively small, water source, heating source, and air source connect to extraction and concentration unit is quite easy.

8. The extractant from the biomass will go through the whole system as a pre-designed workflow.

9. It can be used either to get wanted ingredients or evaporate out the unwanted matter; suitable for essential oil, volatile oil and aromatic oil; juice, medicine liquid, tea and etc.

10. The extraction and concentration process practice several times in this system to improve the efficiency of raw material biomass; solvents can be recycled to reduce production cost.

Extraction Machine Options for Multiple Functions

To increase the proficiency and efficiency of this extraction and concentration machine, there are several options the user can choose to add to the system.

Heating Source

Heating source is electric heating, steam heating, jacket oil heating, and jacket water heating; for plant or herbs that requires no high temperature, we can use hot water jacketed circulating heating where the extraction temperature can reach 90-95℃; Jacket oil heating is faster than water considering the thermal conductivity of oil. Factories have steam source can also apply steam heating to the extracting system. This is the fastest way to heat up. But is not suggested for heat-sensitive raw material extraction.

Stirring and Ultrasonic System

To install a set of stirrer into the extraction tank can speed up the process of biomass soaking. Or we can use ultrasonic extraction. Use a concentrating ultrasonic generator, due to the unique physical and cavitation effects of ultrasonic waves, it can promote the breakage or deformation of plant cell tissues, vibrations, acceleration shocks, and sound pressure between solute particles allowing the large volume of herbal medicinal materials to fully contact the ultrasonic probe, which accelerates the uniform precipitation of active ingredients in the substance. Thus the extraction rate is significantly improved than that of traditional processes. Ultrasonic extraction is normal temperature extraction, which effectively reduces the loss of heat-sensitive components. There is a selectable frequency range: 15KHz、20KHz、28 KHz、30 KHz、35 KHz、40 KHz、50 KHz、60KHZ

Extraction and Evaporation System Main Parameter

Model 50L 100L 200L 300L 500L Pre-cool Tank 100 L 200 L 400 L 300*2 L 500*2 L Extractor 50 100 200 300 500 0.3 Jacket Design Pressure 0.75Kw 1.1 Kw 1.1 Kw 1.1 Kw 1.5 Kw Alcohol Tank 50 L 100 L 200 L 300 L 500 L 0.3 Jacket Design Pressure 0.25 Kw 0.25 Kw 0.37 Kw 0.55 Kw 0.75 Kw Single-Effect evaporator 40 Kg/h 70 Kg/h 125 Kg/h 200 Kg/h 300 Kg/h 0.6 m2 heating 1.2 m2heating 2.4 m2heating 3.8 m2heating 5.7 m2heating 1.7 m2cooling 3.5 m2cooling 7 m2cooling 9.7 m2cooling 14.5 m2cooling Liquid Pump 0.55Kw Power Vacuum Pump 1.5Kw 1.5 Kw 1.5 Kw 2.2 Kw 3 Kw Steam Consumption 35Kg/h 55 Kg/h 100 Kg/h 140 Kg/h 210 Kg/h Dimension mm 2500*900*2000 3000*900*2400 3600*1000*2600 4500*1100*2800 6000*1400*3200

Industrial Extraction and Evaporation Tank

Check out more for mass production extraction tanks.

Reviews

There are no reviews yet.