Description

Stainless Steel Liquid Filter for Fast Flowrate

The Stainless Steel Liquid Filter for Fast Flowrate is developed for large-diameter and high-speed pipelines. The filter area of the filter element is several times that of the traditional ordinary filter element, which is suitable for high-throughput working conditions, especially in the field of water treatment.

The large flow liquid filter has the characteristics of large connection size, large flux, and small footprint, which can effectively solve the problems of high investment cost, long replacement time, and troublesome operation of traditional filters, thereby reducing investment costs and operating costs. Save labor resources.

The large-capacity sanitary liquid filter is available in vertical and horizontal structures. Filters equipped with 20″ and 40″ filter elements usually adopt a vertical structure; the filter media system flow of a 60″ filter element is generally above 1000T/H, so the horizontal structure is selected to meet the large flow rate and reduce the number of filter element replacements. The filter element is more convenient.

Operation Conditions

Max. Operation Pressure: 0.6-1.0Mpa.

Max. Temperature: 150℃.

Contact Parts Material (shell and valve): 304 or 316L as optional.

Sealing Ring& Gasket: EPDM, PTFE, VITON, SILICA

Surface Finish: 1# mechanical polishing or 2# electrolytic polishing

Polishing: ≤0.6μm inside, ≤0.8μm outside.

Connection of Shell: Flange.

Connection of In-outlet: Flange,Tri-clamp.

Connection of other port (valves and instruments, option): Thread.

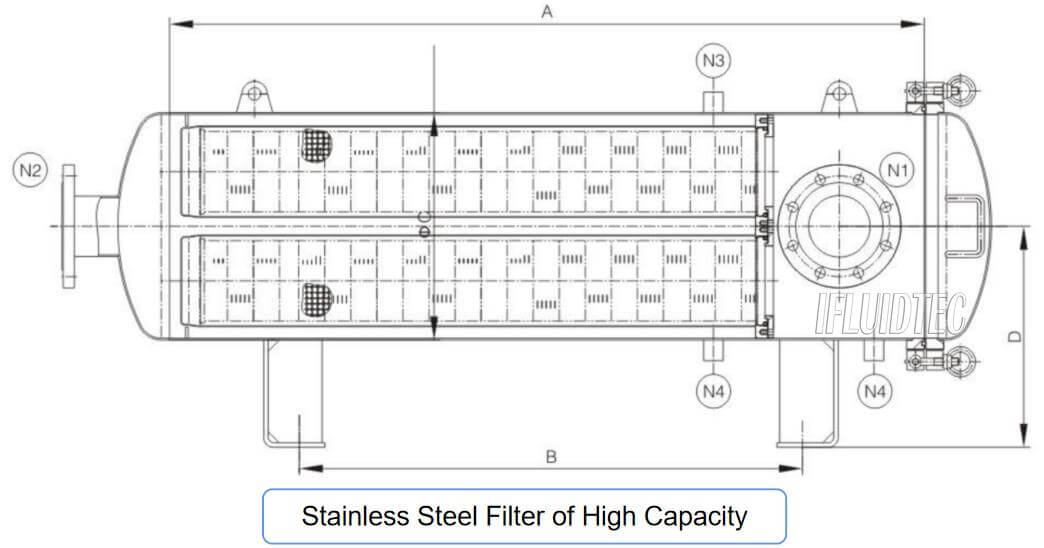

Stainless Steel Liquid Filter for Large Flowrate Structure

Large Flow Sanitary Liquid Filter Dimension

| Cartridge Size | Qty. Cartridge | Construction Type | Length(A) | Length(B) | Diameter of Shell(C) | Height(D) | Diameter of In-outlet |

| 20" | 1R | Vertical | 700 | 300 | Ø230 | 355 | 2",2.5",3" |

| 2R | 800 | 400 | Ø400 | 395 | 3",4",5" | ||

| 40" | 1R | Vertical | 1200 | 600 | Ø230 | 355 | 2",2.5",3" |

| 2R | 1300 | 700 | Ø400 | 395 | 3",4",5" | ||

| 60" | 1R | Horizontal | 1700 | 900 | Ø230 | 355 | 2",2.5",3" |

| 2R | 1800 | 1000 | Ø400 | 395 | 3",4",5" | ||

| The above table is standard data, which can be customized according to customer requirements. |

Reviews

There are no reviews yet.