Description

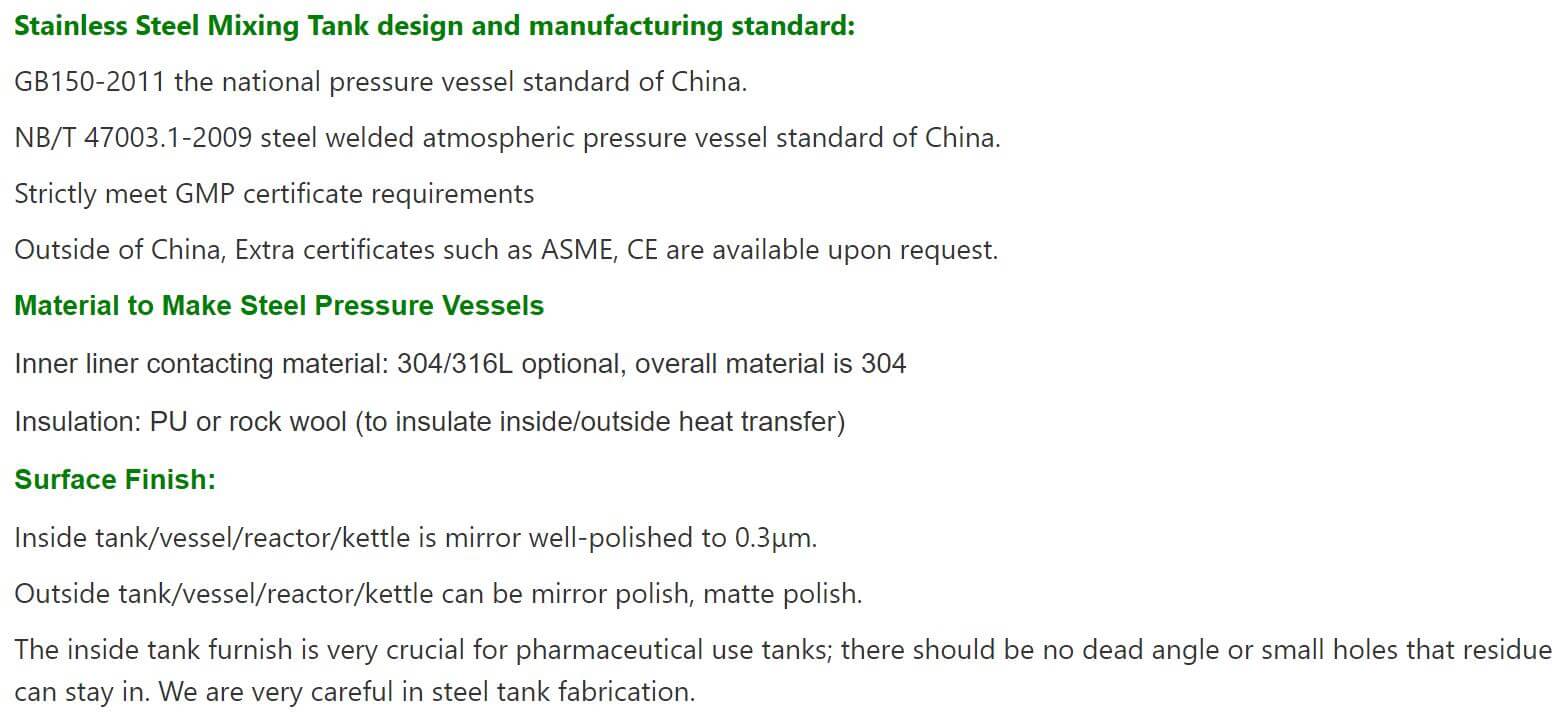

Stainless Steel Mixing Tank of Food, Chemical& Pharma Use

Stainless Steel Mixing Tank Application

Stainless Steel Mixing Tank has a wide range of applications in various industries such as pharmaceutical, chemical, cosmetic, food, and beverage. The classification of mixing tank is so wide, we will introduce you with some of them that are within our manufacturing ability.

Liquid mixing tank, milk mixing tank, syrup preparation tank, injection water tank, dissolving tank, jacketed heating mixing tank, jacketed cooling tank, pharmaceutical tank, stainless steel tank with agitator, pharmaceutical vessels, chemical mixing vessel, stainless steel jacketed mixing tank, magnetic stir tank.

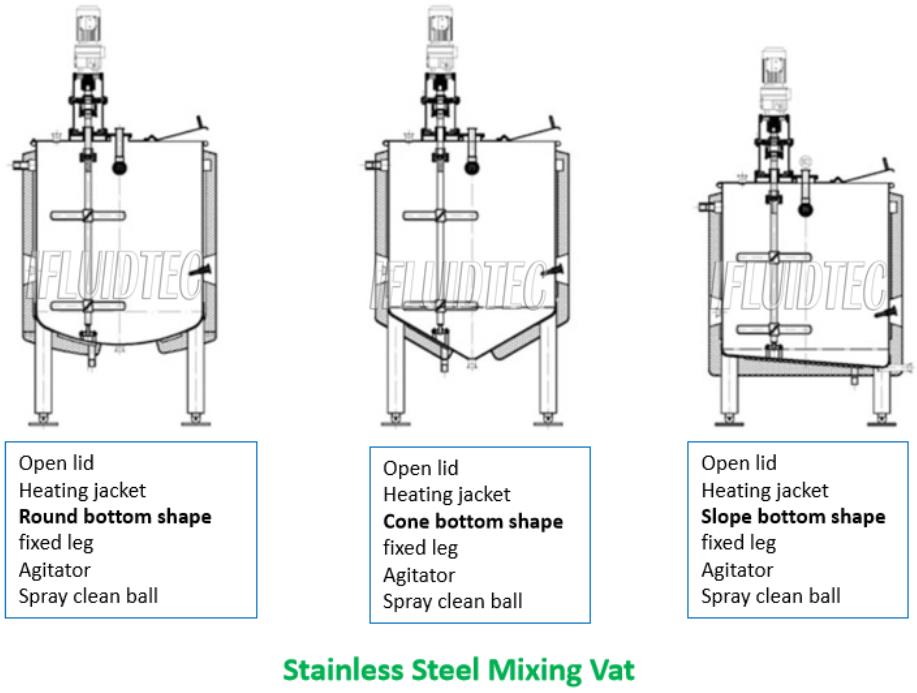

Mixing Tank Bottom Options

Jacketed Mixing Tank Jacket Options

There are several types to make heating or cooling jacket for a mixing tank.

1# Full Jacket

Usually used for liquid heating and cooling media that run through vessel jackets. Considering jacket pressure determines the vessel wall thickness, also results in tank manufacturing cost, such jackets are more suitable for the low-pressure tank.

2# Coil jacket/half-Pipe Jackets

Useful for high pressures, half-pipe jackets are better for liquid than for steam. The heating or cooling media runs through the coil, zooming those areas. Theoretically, the space between coils the smaller the better for heat transfer; but due to operation difficulty, a 19mm distance is recommended. When reaches a certain coefficient, such space does not impact heat transfer efficiency. This is suitable for the high-pressure vessel.

3# Dimpled jacket

suitable for larger vessels, it can save stainless steel plate raw material, in a way to lower cost. But the pressure is better <3.5bar.

Media go inside the vessel jacket can be steam, hot water, cooling water and oil upon mixing need. Usually, a circulation system is adopted in the mixing system to increase efficiency and reduce waste.

Mixing Tank Baffle Options

Mixing tanks with baffles can scrap off material that sticks to the tank wall. Many paste-like solutions like cream, sun cream need it which can save raw material waste. For products like water, juice, syrup, the mixing baffles are not very helpful.

Mixing Vessel Size Choices

About the tank size, theoretically, we can make any size that asked by clients, but normally, we make 50L, 100L, 150litre and integer number size of tanks.

Below is a table to convert between US gallon and Litre

| Gallon (US)[ [gal (US)] | Liter [L,l] |

| 0.01gal (US) | 0.03785411784L,l |

| 0.1gal (US) | 0.3785411784L,l |

| 1gal (US) | 3.785411784L,l |

| 2gal (US) | 7.570823568L,l |

| 3gal (US) | 11.356235352L,l |

| 5gal (US) | 18.92705892L,l |

| 10gal (US) | 37.85411784L,l |

| 20gal (US) | 75.70823568L,l |

| 50gal (US) | 189.2705892L,l |

| 100gal (US) | 378.5411784L,l |

| 1000gal (US) | 3785.411784L,l |

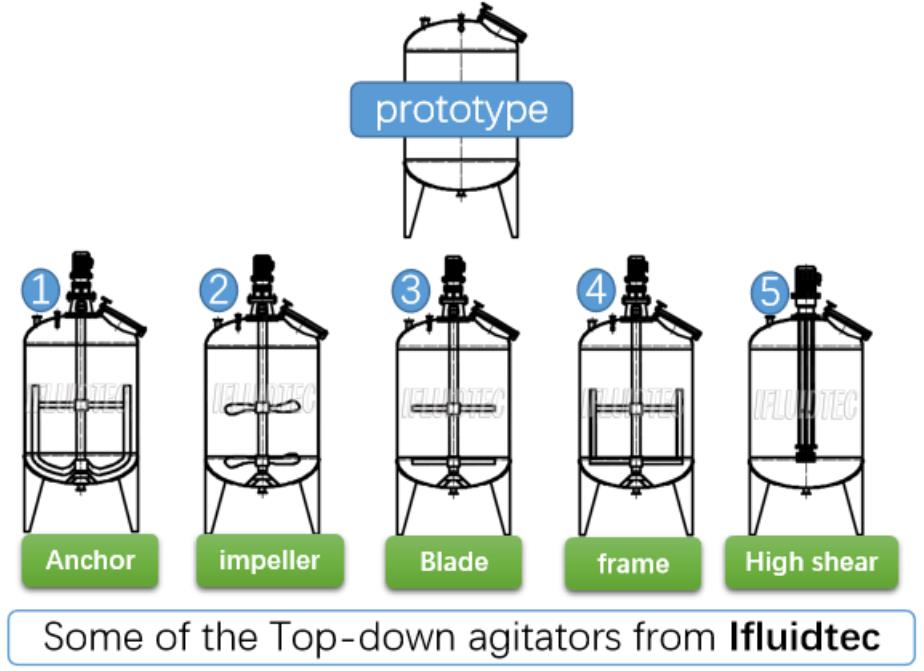

Different Types of Agitators inside Mixing Tank

The agitator plays a great deal in material mixing, dispersing, dissolving, stirring and emulsifying& homogenIzing. Various designs come up to meet users’ needs in our years of tank manufacturing projects in dairy, beer, wine, fermentation, bioreaction, chemical, pharmaceutical, and other fields. There are many aspects to consider, to name a few:

1. The stirring speed and electricity power of agitators are carefully calculated, selected; more viscous material, bigger power and stronger shaft and agitators.

2. Whether the motor is directly driving agitator or via reducer gearbox;

3. Whether motor installed top-down or bottom-up, vertically or horizontally.

4. What size of mixing shaft should be strong enough.

5. The height of the jacketed mixing vessel.

6. The kind of mechanical seal or lipseal is used.

There is a wide range of ‘types of agitators’ that we can install into our mixing tanks. Each agitator works well on certain material and certain production conditions. Below shows some types of agitators, for the buyer who doesn’t know how to choose, feel free to contact us, we will provide professional advice. For agitator not showing above, contact us for more info.

Tags: Blade agitator, Paddles agitator, Impeller agitator, Ribbon mixer, vortex mixer, Umbrella mixer, Dispersion mixer, High shear mixer, High shear homogenizer, Turbine stirrer, Anchor stirrer, Propeller stirrer, Frame agitator

How to check the mixing vessel factors point by point?

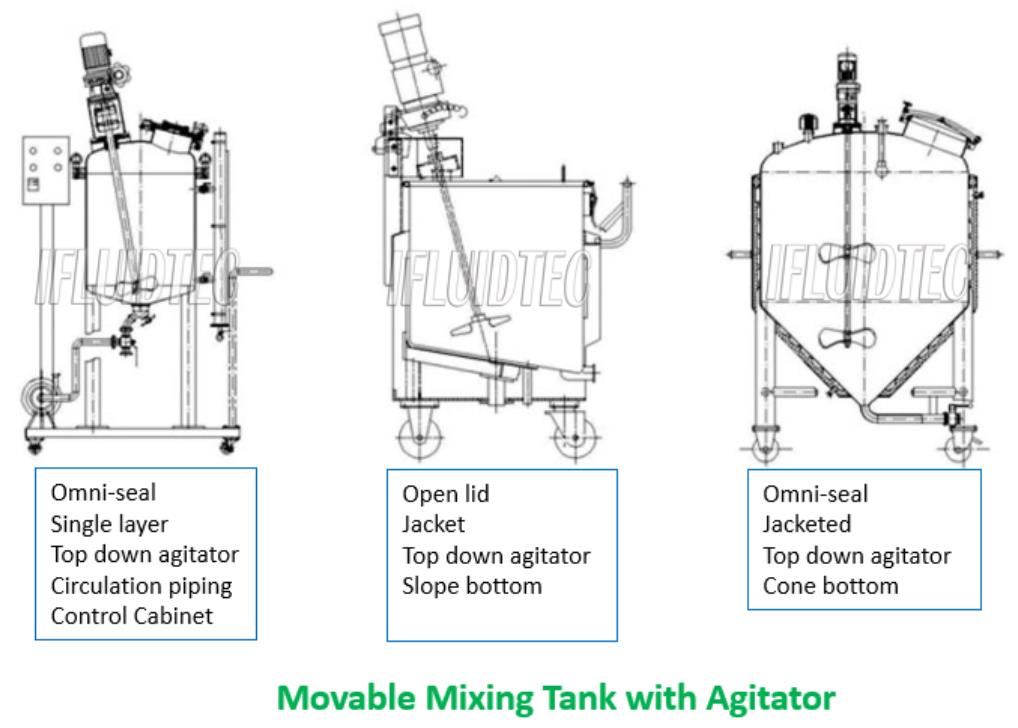

To help buyers to make an easy decision, they can follow a few aspects of the tank as the first step to communicate with supplier. Firstly to consider the material property such as fluidity and viscosity to decide agitator type; Secondly, to decide tank size, our using coefficient is 0.6-0.8 upon materials. Thirdly, to decide whether material needs heating or cooling during dosage or preparation and also the working temperature. Fourthly, is the vacuum or pressure needed in material loading or discharging. Fifthly, prefer tank to be fixed on the ground or movable, normally tank ≥500Liter is not suggested to move around due to its weight after filled. It will hit walls or hurt operators perhaps during moving. Sixthly, room height, most factories have limitations for room height while the tank always turns out to be the highest device in a production line. Sevenly, your budget. Most steel tank buyers are not willing to tell supplier the budget, they are afraid the seller will take advantage of that info. But the truth is that professional tank manufacturers like us always design the best, while exceeds the buyer’s ability to pay. Thus waste too much time to change drawings again and again. As introduced, there are so many choices and modification in stainless steel tanks, we can always adjust upon real need. And the price is always related to quality.

Various Usage of Stainless Steel Mixing Vessel

Other Demonstrations

A pressure conversion table for reference.

bar psi kPa MPa bar psi kPa MPa bar psi kPa MPa 1 14.5 100 0.1 10 145 1,000 1 100 1,450 10,000 10 2 29.0 200 0.2 20 290 2,000 2 200 2,900 20,000 20 3 43.5 300 0.3 30 435 3,000 3 300 4,350 30,000 30 4 58.0 400 0.4 40 580 4,000 4 400 5,800 40,000 40 5 72.5 500 0.5 50 725 5,000 5 500 7,250 50,000 50 6 87.0 600 0.6 60 870 6,000 6 600 8,700 60,000 60 7 101.5 700 0.7 70 1,015 7,000 7 700 10,150 70,000 70 8 116.0 800 0.8 80 1,160 8,000 8 800 11,600 80,000 80 9 130.5 900 0.9 90 1,305 9,000 9 900 13,050 90,000 90

Stainless Steel Vessel Fittings

Tags: Stainless Steel Mixing Tank, magnetic agitator stirring tank, Stainless Steel Tank with agitator, inline mixer design, jacketed Mixing Tank, stainless steel tank fitting and spare parts, jacketed stainless steel tank, high shear mixing tank, stainless steel storage tank

Reviews

There are no reviews yet.