Description

Aseptic Magnetic Agitator Mixing Tank

What magnetic mixing tank can have?

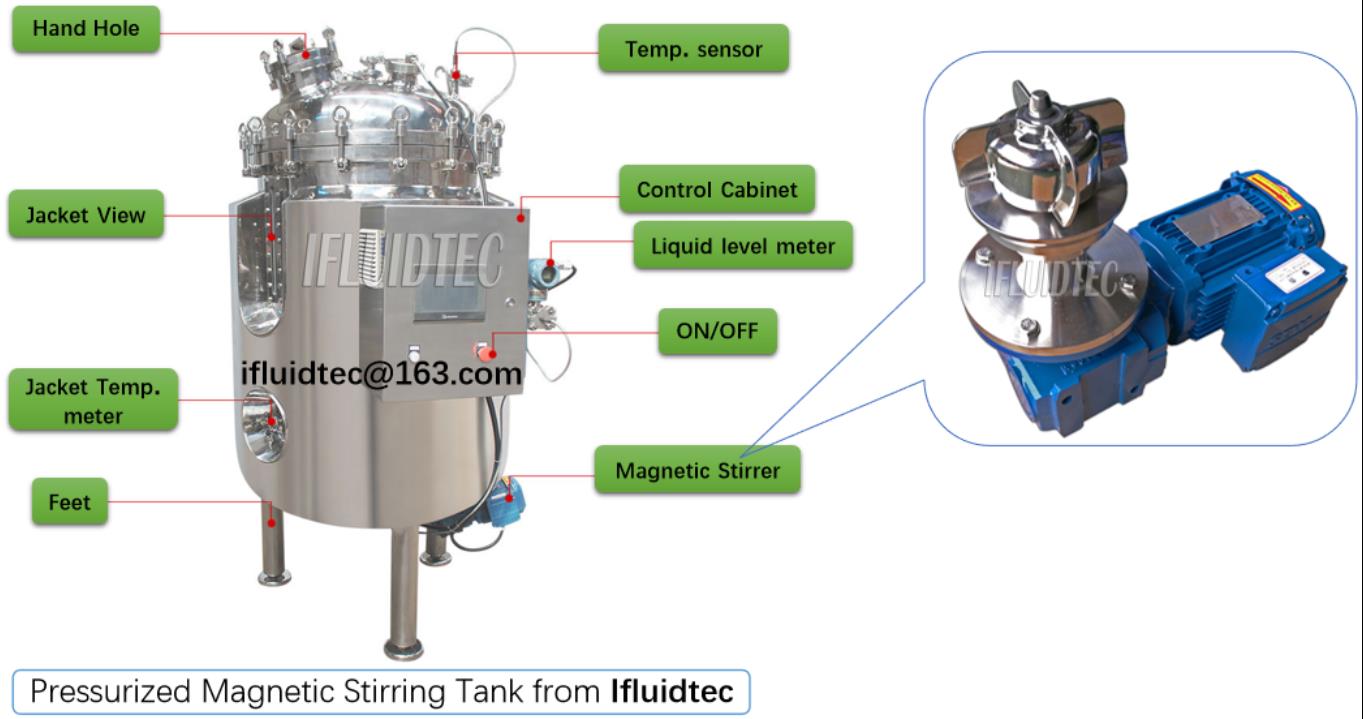

Magnetic stirring mixing tank is mainly composed of one tank and one magnetic agitator; other auxiliary spare parts can be installed onto this mixing system including sterile air filter, digital thermometer, PH tester, steam sterilization port, viewable sight glass, manhole, handhole, inlet and outlet, CIP spray cleaning ball, pressure gauge, sampling valve (installed at bottom of stainless steel tank), liquid level gauge. We can also provide a control system to make the manual operated magnetic mixer up to an automatic control level which is available for buyer’s options.

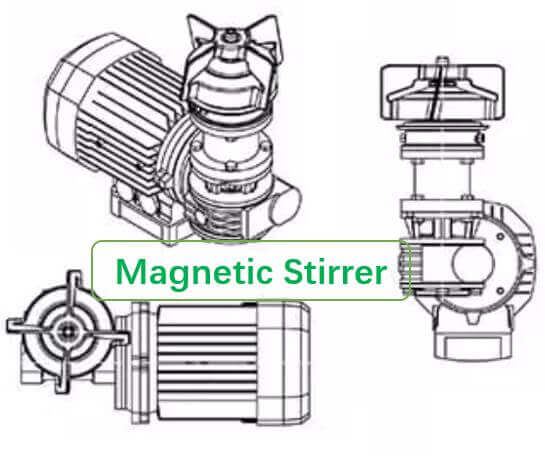

Obvious advantages of magnetic stirrer

We have been explained a lot about mixing tank in another post on ‘stainless steel mixing tank’; so here just skip the detail and focus on the introduction of the magnetic stirrer.

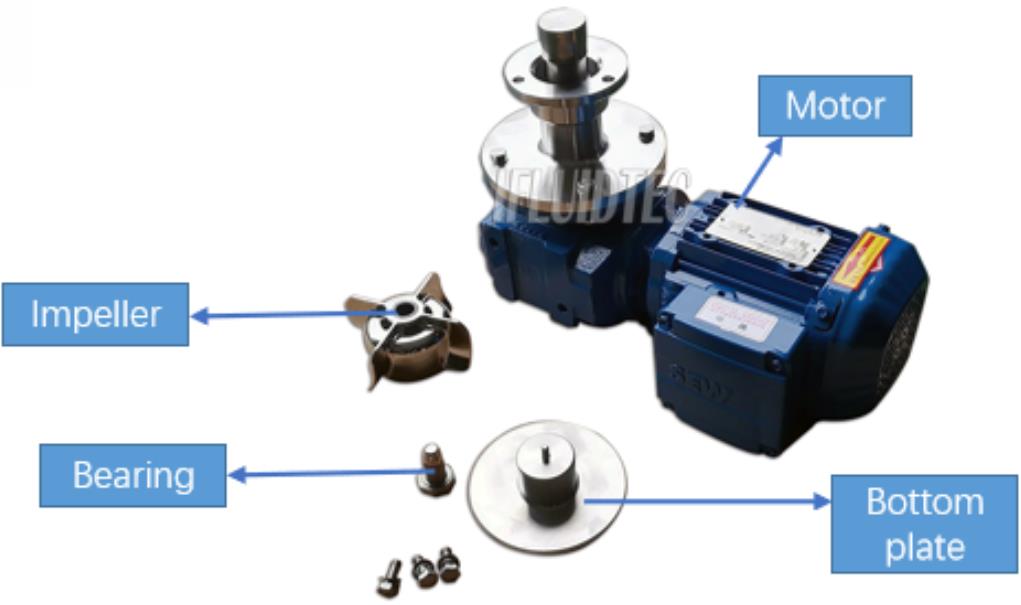

The most appealing advantage of the magnetic mixers is that it can be used for aseptic and sterile liquid mixing. It uses the static seal instead of the conventional dynamic seal which solves the potential risk of leakage from the mechanical seal. The mixing shaft is driven by the permanent magnet coupling. And the material contact part is using fine stainless steel 316L/304 conform to GMP standard.

Compact and clever design, simple structure, very low maintenance, no dead angle very easy to clean. The contamination test is approved under various production conditions.

Magnetic agitator adopts motor direct driven, very low noise, steady in rotating and speed adjusting. The agitator is with features of high-temperature resistance, abrasion resistance, chemical corrosion resistance, strong magnetism.

Powder or liquid is sucked into a vortex generated by the magnetic impeller rotates rapidly. The centrifugal force of impeller rotation works on the material in a way of radiation. The material rises and circulates continuously to reach the stirring, mixing, dissolving, dispersing and homogenizing results.

Surface Finish:

Inside tank/vessel/reactor/kettle is mirror well-polished to 0.3μm.

Outside tank/vessel/reactor/kettle can be mirror polish, matte polish.

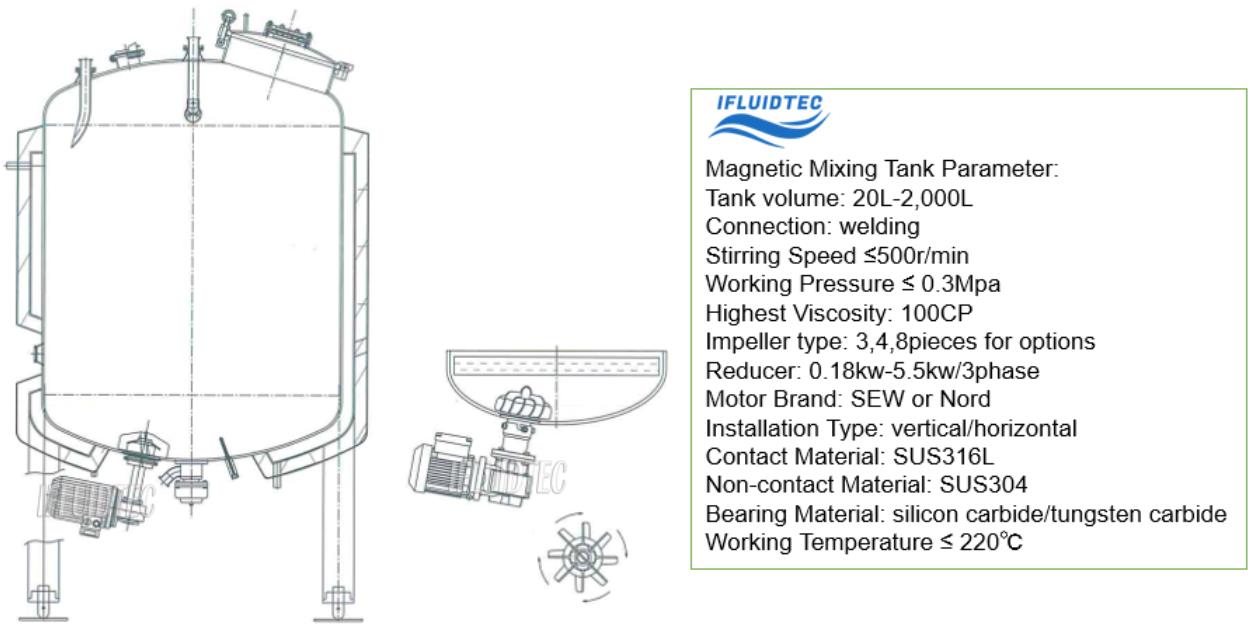

Magnetic Mixing Tank Parameter: Open for customizing

Tank volume: 20L-2,000L

Connection: welding

Stirring Speed ≤500r/min

Working Pressure ≤ 0.3Mpa

Highest Viscosity: 100CP, magnetic stirrer is not suitable for material for high viscosity material or material that is a high sugar content or sticky.

Impeller type: 3,4,8pieces for options, the buyer can have more blades on the impeller as needed.

Reducer: 0.18kw-5.5kw/3phase

Motor Brand: Chinese brand or SEW or Nord upon requirement.

Contact Material: SUS316L

Non-contact Material: SUS304

Bearing Material: silicon carbide/tungsten carbide

Working Temperature ≤ 220℃

Magnetic Mixing Vessel Parameter

| Model | Motor/kW | Tank Size/L | Speed RPM |

| MGS-20 | 0.2 | 50-200 | 120-1400 |

| 0.4 | 50-200 | ||

| MGS-40 | 0.55 | 200-500 | |

| 0.75 | 200-500 | ||

| MGS-60 | 1.1 | 500-1000 | |

| 1.5 | 500-1000 | ||

| MGS-80 | 1.5 | 800-2000 | |

| 2.2 | 500-1000 |

Reviews

There are no reviews yet.