Description

Subcritical Water Extraction System

Overall performance of the Subcritical Water Extraction System

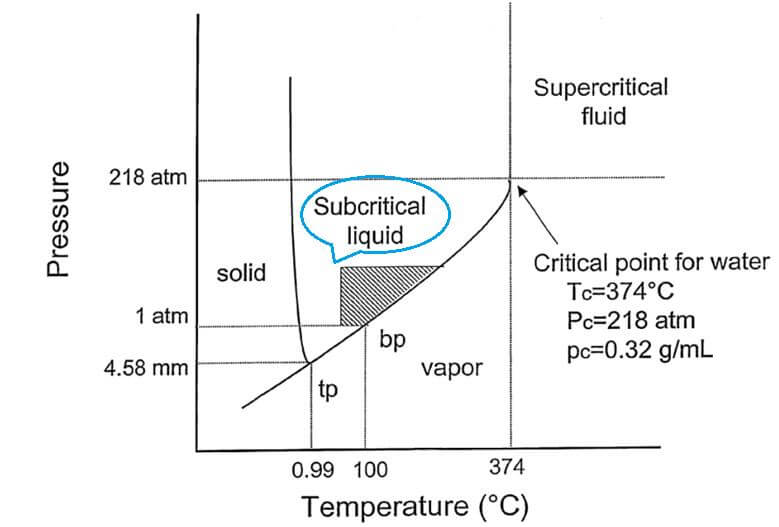

Subcritical Water Extraction System (shortened as SWE) is a new and powerful technique that extracts at temperatures between 100~374℃ and pressure high enough to maintain the liquid state (Fig.1). water has unique properties like a disproportionately high boiling point for its mass, a high dielectric constant, and high polarity. When the temperature rises, there is a marked and systematic decrease in permittivity, an increase in the diffusion rate, and a decrease in the viscosity and surface tension. Thus, more polar target materials of high solubility in water are extracted most efficiently at lower temperatures and at ambient conditions.

This project is based on subcritical water, at a certain temperature and pressure, the pretreated raw material is loaded into the extractor, and the system is successively subjected to leaching, solid-liquid separation, evaporating, etc. process. Finally, get target ingredients.

Evaporation Condition Range of Subcritical Water Extraction System

| Extracting temperature | 120℃-200℃ |

| Extracting pressure | <2.5MPa |

| Vacuum degree | -0.95 |

| Power | AC380V/ 50Hz |

| Room temperature | -10~45℃ |

Advantages

- Usewater as an extraction solvent is safe, non-toxic, non-flammable, and environmentally friendly.

- Water is easily and commonly available and costs very

- The better diffusivity of the solvent shortens extraction time.

- Since water is no pollution, reduces effluent reprocessing costs and eliminates VOC (volatile organic compound) emissions.

- Obtained extracts are safe, have no trace of any toxic solvents.

- There is no residual content of potentially toxic solvents in the obtained extracts.

- Transport costs linked to solvent supply and recycling are considerably reduced or even eliminated.

- SWEsubcritical water extraction is applicable for the extraction of low-polar as well as non-polar compounds.

This process thus clearly corresponds to requirements for safer, more eco-protective chemistry.

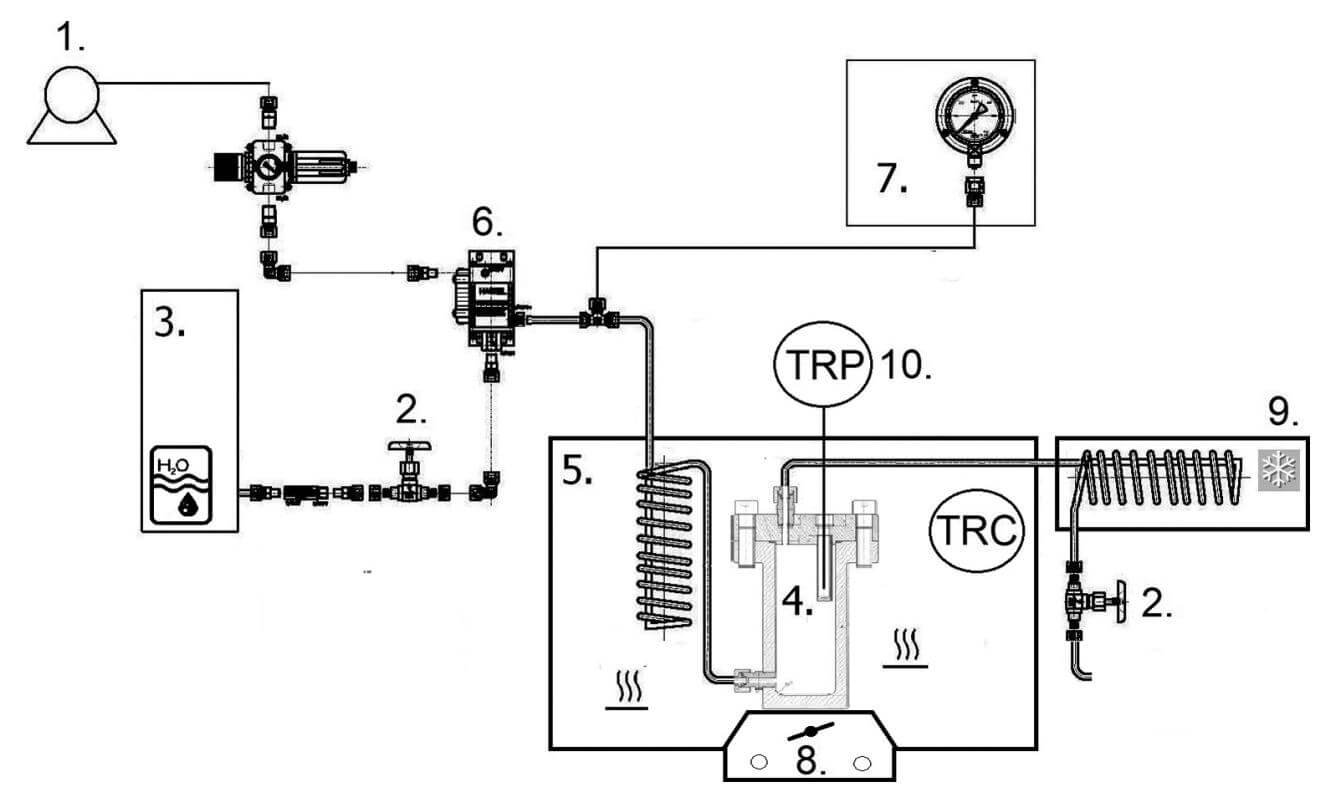

The main parts of a dynamic SWE system

- Compressor

- Valves

- Water tank

- Extractor

- Oven

- Pump

- Manometer

- Magnetic stirrer (Optional)

- Cooling coil (bath)

- TRP and TRC

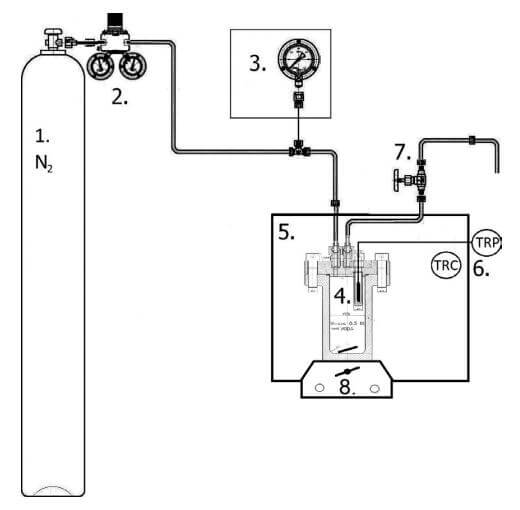

The main parts of a static SWE system (Faculty of Food Technology of Osijek)

- N2 tank

- Pressure reducing valve (200/50)

- Manometer

- Extractor

- Oven

- TRC and TRP

- Valve

- Magnetic stirrer

What components our SWE system contains

- Extractor

- Plunger pump

- Evaporator

- Hot oil tank

- Hot oil pump

- Vacuum pump

- Circulating water tank

- Stainless steel pipe

- Stainless steel frame

- Stainless steel valve

- Safety valve

- Electric heaters

- Switch control cabinet

- Cable

- Accessories, tools

Reviews

There are no reviews yet.