Description

Supercritical CO2 Extractor|CO2 Extraction Machine

Supercritical Fluid Extraction Machine-SFE CO2 Extractor Review

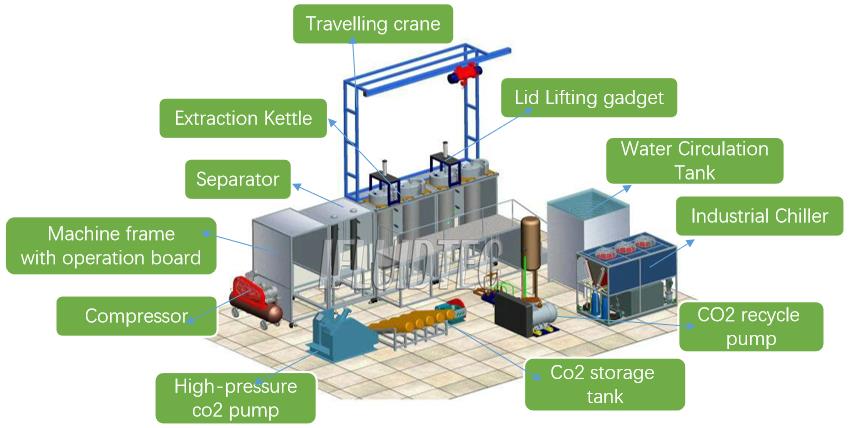

Supercritical CO2 Extraction Machine Crucial Parts

A full set of cox extraction extractor that designed for industrial use purposes mainly contains components such as co2 extractor, separation tank, fine distillation column, co2 high-pressure pump, entrainer pump, refrigerating system, heat exchange system, purifying system, pressure stabilizing system of extraction kettle, co2 storage tank, flow meter, temperature, and pressure control (protection) system, etc.

1. Extraction Kettle

where crushed dry or wet raw material put; the extractor works under high pressure about 40-50Mpa; the extraction tank can be manufactured from small lab size to industrial big volume, ranging from 0.5L, 1Liter to 200L per extraction kettle. 2L. 5L/50Mpa. For lab size co2 extractor, the kettle can be taken out and loaded manually. But for big size where the extractor is so heavy, we will make traveling crane and lifting clamp on top of each kettle. The kettle can be lifted up by the above crane.

2. Separation Kettle/Separator

to match the extractor usage need, the separation tank has sizes from 0.3liter to 100L. The effective ingredients come down from the bottom of separators.

З.Fіnе Dіѕtіllаtіоn Соlumn(not shown in above FIG.)

certain raw material needs to be distilled and purified under the impact of distillation. So the whole co2 extraction system can either have this distillation column or not depends on the raw material property. But if the buyer has many types of materials to be extracted, we suggest them to have a full complete set of co2 oil extractor multiple functions. The distillation column can be designed with 4 sections, 6section or more. So the user can use the co2 oil extractors in three ways:

A. Use extractor and separator only.

B. Use extractor, separator, and distillation by the workflow steps.

C. Jump directly to distillation, the material does not go via extraction or separation.

4. High-Pressure co2 Pump

where liquid co2 runs through and pumped out to extractor with very high pressure. Bigger overall co2 extractor requires a bigger power pressure pump. Normally, we design like this 20L with 40Mpa; 50L/50Mpa, 400L/40Mpa, and 800L/40Mpa of single, double or triple-plunger frequency-regulating. A cooling system is installed at the pump core to protect over-heating or dry burning.

5. Co-Solvent Pump

during the co2 extraction process, certain material reaches the best efficiency under the help of co-solvent besides co2. In this way, the co2 extraction system usually comes with an extra co-solvent pump. The co-solvent works as a catalyzer to maximize the limitation for a wider application.

6. Cooling System

equipped with a semi-closed loop a full closed-loop compressor to meet the cooling capacity technological requirement. A set of industrial water chiller and water storage tank will be installed to make the co2 extraction process go on successfully.

7. Heat Exchange and Temperature Control System

according to PID, the extractor, separator, and distilling column are equipped with heating and cooling systems and independent temperature control systems. For water circulation temperature range: room temp. to 85℃; The oil circulation temperature range: room temp. to 150℃; For CO2 fluid accuracy is ±1℃ using digital display temperature gauges.

8. Carbon Dioxide Recycle Pump

even though our closed-loop CO2 extractor has a build-in co2 circulation system where users can save energy consumption; still, a certain percentage of co2 will be wasted. So an extra CO2 recovery pump can be chosen to installed into the extraction machine too to increase the utilization of solvent.

8. Pressure Control (Protection)

an electro connecting pressure gauge is installed at the outlet of the high-pressure pump and set the working pressure to release pressure and make automatic protection in case overpressure occurs; Safety valves are allocated with equipped with high-pressure co2 pump, co2 extraction kettle, separation kettle, and distillation column according to their maximum working pressures to release pressure and make automatic protection in case overpressure occurs; back-pressure valve system at the outlet of the extraction kettle has a counterbalance pressure valve with accuracy ±0.1Mpa.

9.Pipelines

all containers, valves, pipe fittings and pipelines contacting with fluid are all made of stainless steel.

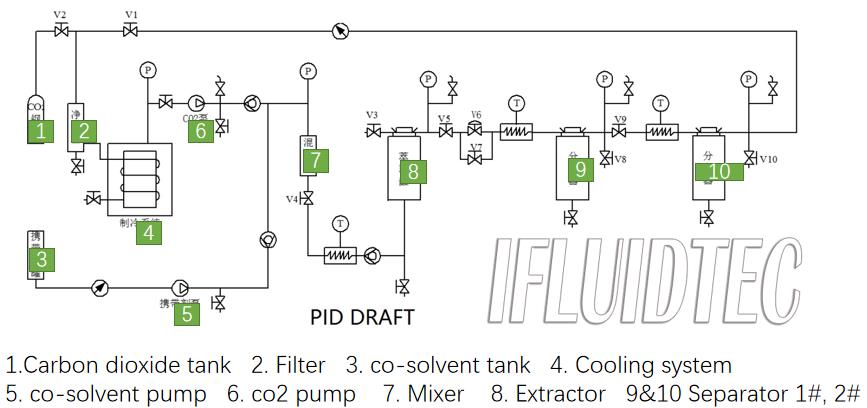

Supercritical CO2 Extraction Process PID(only for reference, can be customized upon user’s requirement)

1.Carbon dioxide tank 2. Filter 3. co-solvent tank 4. Cooling system 5. co-solvent pump 6. co2 pump 7. Mixer 8. Extractor 9&10 Separator 1#, 2#; other needed valves, temperature gauges, pressure gauges, connections, pipings to make a mechanical structure.

Supercritical Fluid Extraction Machine(SFE machine)-co2 extractor Applications.

Due to the clean and pure extraction of carbon dioxide/co2 oil extraction process; also because of the closed-loop of co2 circulation within supercritical extraction equipment, the co2 cost itself is cheap; and for the account of extracting temperature is almost near to ambient well protected the active ingredients that we want. The supercritical extraction machine becomes more and more accepted and welcomed by the pharmaceutical industry for valuable oil. So let’s take a look at the application.

Pharmaceutical Industry: Chinese herbs extraction and concentration, separation, refinement, distillation, precipitation and etc.,

Food Industry: Hops Extraction, caffeine removal from the coffee bean, purification of vegetable oil or animal fat; essential oil extraction, fragrance extraction, and extraction pigment from plants.

Perfumery Industry: Separation and refinement of natural perfumeries or synthetic perfumeries, de-alkalization of tobacco, extraction of raw material for cosmetics usage.

Chemical Industry: Separation of hydrocarbon, refinement of organic synthetic ingredients, separation of an azeotrope, retrieval of raw materials during the reaction, dehydration of organic solution that contains water-soluble objects, water oxidation.

Other: Superconducting, semiconductor, ceramics, oil washing of petroleum core, enzyme catalytic reaction.

CO2 Oil Extractor Performance Characteristics:

♦A set of a highly integrated system with all necessary parts ready.

♦Whole system assembled and tested at the factory before loading, sure installation, and training at the user site.

♦Working pressure 30Mpa- 50Mpa(Max.500 Bar, 7250psi); very secured design and manufacturing.

♦Digital Type Pressure and temperature gauge, easy set, easy read.

♦CO2 self-circulation within the extraction system; saves co2 waste and extra recycling is optional.

♦A high-pressure pump boosts pressure instantly, efficiently.

♦Imported USA good quality counterbalance pressure regulator.

♦A very wise choice for heat-sensitive material.

♦Fast extraction and complete extraction, co2 non-toxicity, non-flammable, non-pollution.

Supercritical CO2 Extractor Models and Sizes

| No. | Name | Data |

| 1 | Extractor (quick-open type) | 50L/40Mpa |

| 2 | Material canister | To hold raw materials |

| 3 | First stage separator | 25MPa |

| 4 | Second stage separator | 25MPa |

| 5 | Mixer | 40MPa |

| 6 | Purifying filter | 16MPa |

| 7 | Pre-heater | 75℃ |

| 8 | CO2 storage tank | 16MPa |

| 9 | Refrigerator/chiller | 25,000 Kcal |

| 10 | CO2 high-pressure pump | 0-1000L/h, 40MPa |

| 11 | Co-solvent pump | 40Mpa |

| 12 | CO2 recovery pump | Optional; to save CO2 |

| 13 | Electric lifting system | Electric-driven type, low noise |

| 14 | Flowmeter | Instantaneous flow & cumulative flow |

| 15 | Co-solvent pump flow meter | |

| 16 | Temp. and pressure controller | Digital or analog (optional) |

| 17 | Electric current meter | Detect instant current |

| 18 | Safety valve | To keep the system in safety |

| 19 | Electrical elements | UL certified ABB or Schneider, etc |

| 20 | counterbalance valve | TESCOM |

| 21 | High-pressure pipe and fitting | Stainless steel 304 |

| 22 | Unloading device | Help unloading of spent raw material |

| 23 | Frequency converter | For CO2 high-pressure pump and Co-solvent pump |

| 24 | Operation platform | Stainless steel |

| 25 | CO2 cylinder frame/CO2 | Carbon steel |

| In view of ongoing product improvements, designs and specifications are subject to change without notice. Joysun can accept no responsibility for possible errors in catalogs, brochures or any other printed material. | ||

With the concern and guidance of experts and scholars from Tsinghua University subordinated units of the Chinese Academy of Sciences, we have localized research &produce Supercritical CO2 extraction machine. For more than 10 years, we have owned the ability to make serial production for small and medium test (production) devices. Our products have sold nationwide and exported to foreign countries.

Our Supercritical extraction machine has passed through the authentication of ISO9001:2000 International Quality Management System. The company has solid technology, excellent department, and complete test and inspection means as well as perfect after-sale service. Our laboratory has a sample machine which can be used for testing new samples for clients.

Below are some constantly asked questions concerning buyers for the supercritical fluid extraction system.

1. Can CO2 extractor also use other solvents like alcohol?

Sometimes, yes. Alcohol or not depends on the material (can’t be absolute; e.g. HEMP extraction, no need alcohol); some material needs alcohol to speed up extraction or to get a more valuable result.

2. What is final product from CO2 machine only oil or other ingredient too?

For highly oily material, like seeds; come out as oil; for hemp, come out as mixture. The user needs to test the ingredients from extracts.

3. How much is CO2 consumption?

This also depends on the material, but for example for a set of c02 extractor size 24L*2(equal to 50L extractor), the first time charge, 90kg CO2 is needed; if run as continuously, maybe 7-8bottles are needed for 24hours production, each bottle around 20kg.

4. How much CO2 can be recycling?

The cox extractor system itself is with a built-in co2 recovery system that can recycle 60% of carbon dioxide; the user can also buy an extra co2 recycling pump to increase the recovery rate to 80-90%.

5. How much is the production cost per extraction batch? of the cost to finish one 50 litter batch?

Well, we have many models of supercritical extraction machine/SFE system; we’d like to give a general data based on a 50L extractor. Power consumption: 50kw*3hour; CO2 consumption: 30kg/ circle

6. How much of the maintenance cost per year?

If you have a good operator, there will be little maintenance; sealing rings depends on the machine use frequency.

7. If a user wants to test, how much material should we bring?

The minimum raw material needed for our test is 2kg;

8. What about the training plan for such the co2 oil extraction machine?

We have a detailed training plan including the below content.

♠ Safe training of the equipment such as power, pressure, inflammable and explosive, mechanical drive, health, and so on);

Normal operation method and step;

♠ Material tank load and unload of extractor;

♠ Open and close of extractor and separator;

♠ How to use dry purifier;

♠ The parameter setting and physics meaning of all controlling component;

♠ The operation of high-pressure valve control, flow adjustment, temperature setting, pressure balance, and so on;

♠ The daily maintenance program and method of this device.

Ingredients That Extracted by CO2 Supercritical Extraction Machine

| Pepper oil | Grape seed oil | Evening primrose oil | Barley oil | Fish oil |

| Tobacco essential oil | Ganoderma spore oil | Angelica oil | Walnut oil | Cauliflower oil |

| Resin onion root oil | Kiwi seed oil | Clove oil | Pine pollen oil | Turmeric oil |

| Egg yolk powder phospholipids |

Shikonin wild chrysanthemum oil |

Salvia miltiorrhiza extract |

Shrimp skin red pigment | Seabuckthorn seed oil |

| Wheat germ oil | Lycopene | Dissolving oil | Houttuynia oil | Hop extract |

| Wolfberry seed oil | Ginger oil | Frankincense extract | Ursolic acid | Grass coral extract |

| Andrographis extract | Psyllium oil | Capsicum red pigment | Magnolia extract | Safflower oil |

| Artemisinin | Schisandra oil | Perilla leaf oil | Natural caffeine | White emu oil |

| Propolis antibiotics | Peppermint Oil | Honeysuckle oil | Sesame oil | Garlic oil |

| Ginkgo oil | Nutmeg oil | Bupleurum oil | Cbd oil |

CBD Oil Extraction by using Supercritical CO2 Extraction Machine

With the increasing popularity of cannabis business, people are looking for efficient ways to extract CBD oil(also known as hash oil, honey oil). There are several ways to get cannabis oil such as ethanol extraction under low temperature; BHO extraction using butane as a solvent; and supercritical fluid extraction using co2 as the solvent.

Supercritical Fluid CO2 Extractor Glossary of Terms and Technical Parameter

To help users and buyers a better understanding of what is SFE(supercritical fluid extraction), below is a list of terminology that can be referred to briefly. (if any mistake, please contact us for correction)

Supercritical Fluid

A supercritical fluid ( shorten as SCF) refers to a substance at a certain temperature and pressure that is above its critical point. We can clearly tell whether it is in the gas phase or liquid phase because there is no distinct difference. SCF can permeate solids like a gas, and dissolve materials like a liquid. Besides, when it is near the critical point, changing pressure and temperature even at very small changes will affect greatly the density of the supercritical fluid. Thus the SCF can be “fine-tuned”;

Supercritical Fluid Extraction

Supercritical fluid extraction (abbreviated as SFE) is the process to separate one component (whether unwanted or ideal) from another (the matrix) using the supercritical fluid as the extracting solvent. Extraction can either from a solid matrix or from liquids, the former is most commonly seen.

Supercritical CO2 Extraction

In the process of Supercritical fluid extraction where we use Carbon dioxide (CO2) as SCF is called Supercritical co2 extraction. CO2 is the most used extract solvent due to its versatile property and advantageous performance.

Closed-loop extraction(Round loop extraction):

Co2 Extractor

also known as supercritical co2 extraction machine, is a machine manufactured to fit the SFE extraction process. It is a simpler name instead of the full name.

Co-solvent

Sometimes during co2 extraction, there is a need to modify the solvent property to make the best use of its extremity by using co-solvent such as ethanol or methanol. It works similarly to a catalyzer.

Various Solvents Critical Properties:

References

https://en.wikipedia.org/wiki/Supercritical_fluid

https://en.wikipedia.org/wiki/Supercritical_fluid_extraction

Reviews

There are no reviews yet.