Description

Vacuum Emulsifying Mixer|Vacuum Homogenizer for Sale

Vacuum Emulsifying Mixer Application

Vacuum Homogenizer is very widely and mostly in the below industries and products.

Cosmetics and Body Care Products:

Creams, sunscreen, perfumes, shaving creams, foundation, shampoos, shower gel, lotion, bubble baths, lipsticks, mascara, deodorants, perfume, body fluids, conditioners, hand soap, liquid soaps, toothpaste, colloidal suspensions…

Pharmaceutical Products:

Ointments, gels, eye drops, eye ointments, infusions, suppositories, coatings, emulsions, paraffin emulsions, fat emulsions, vegetable ingredient decomposers, preservatives, serum, vaccines … (Some products require the use of sterile emulsifying units)

Food and Beverage:

Sauces, condiments, mayonnaise, liquid spices, cheese sauce, instant food, baby food, jams, pet food, starch solutions, sodium alginate, fruit juices, vegetable juices, milkshakes, protein drinks, Flavorings…

Chemical Products:

Cleaners, polishes, lubricants, hot melt adhesives, preservatives, wax emulsions, ceramic suspensions, polymer emulsions, silicone emulsions, colloidal solutions, catalyst suspensions, penetrants, insecticides, fungicides…

Types of Vacuum Emulsifying Mixer

We have several designs of vacuum emulsifying mixers to meet different purposes of production. Though the structure seems differently, they are adjusted and changed upon the same vacuum homogenizing work principles.

I. The one with a water pot and an oil pot.

This is mostly seen in cosmetics and body care products manufacturing factories. Even the below vacuum homogenizers look differently. Why? Because we try to make our homogenizing machines are the most cost-effective devices for the buyers to purchase. For example, the smaller size, the simpler design due to the emulsifying tank size less than 150Litre is stable in machine structure. So we can make it a relatively cheaper design to reduce the buyer’s budget burden. As you can see from below FIG. Bigger size vacuum emulsifying machine(≥500L/132gallon), the overall machine stainless steel frame tends to be stronger and sturdier, so that during the homogenization process, the machine is reliable to use.

II. The one without the water pot and oil pot.

Some material only needs the vacuum homogenizing part, can use just a main batching tank. Such emulsifying machine is relatively high when its lid lifted up, in this case, we can install bottom entry homogenizer which will significantly reduce machine height. The buyer can choose to have the cheap version machine with switch, button type electric cabinet; but now the more popular choice is the one with touch screen and PLC control emulsifier machine by which almost all parameter can be set via touch screen, production record, data and time can be kept for future tracing back. This is better for production management.

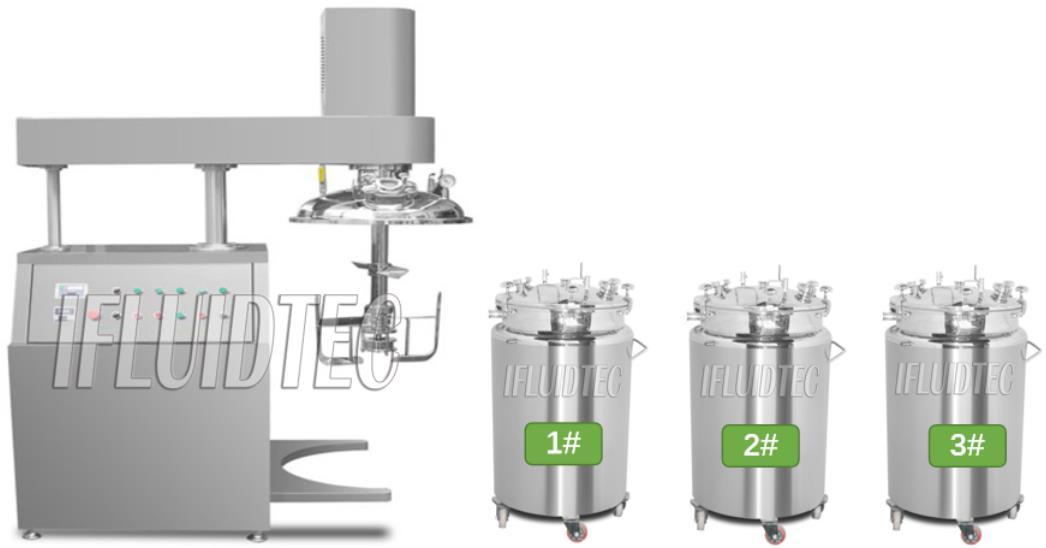

III. The one has no water and oil pots and also the main batching tank can be moved away.

The second batch tank can be used alternatively to speed up work efficiency. Such design is welcomed by manufacturers that have many kinds of products to do while each kind is in small quantity. It’s popular in B2C products.

Vacuum Homogenizer Parameter Table

| Parameters | Model | 100 | 300 | 500 | 1000 | 1500 | 2000 |

| Effective volume(L) | 100 | 300 | 500 | 1000 | 1500 | 2000 | |

| Mixing | Motor power/kW | 1.5 | 2.2 | 3 | 5.5 | 5.5 | 7.5 |

| Mixing RPM | 65(The design can be adjusted according to customer usage) | ||||||

| Emulsification | Motor power/kW | 4 | 4 | 7.5 | 11 | 15 | 18.5 |

| Emulsification RPM | 2P(The design can be adjusted according to customer usage) | ||||||

| Vacuum level(MPa) | -0.09 | ||||||

| Heating type(optional) | Electrical heating or steam heating |

Working Process of Vacuum Emulsifying Mixer

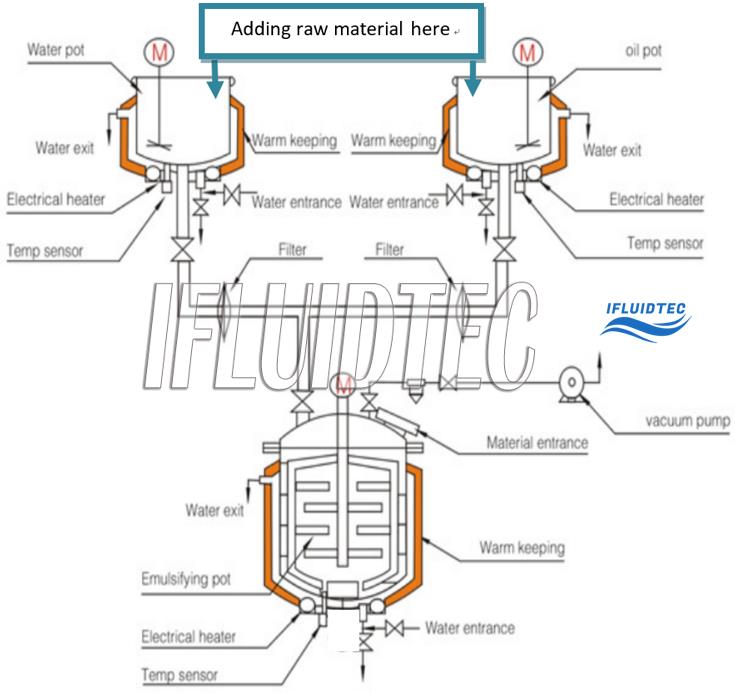

There are three tanks:

Main batching tank(with emulsifier) and preparatory tanks(water phase pot and oil phase pot). For products which need emulsifying, the raw materials are always including water phase material and oil phase material, so the water pot is for preparation of hydrosoluble materials, and oil pot is for preparation of liposoluble materials. The two pots both have the heating jacket layers, which can be heated either by electric heater or steam. Meanwhile, the two pots equip with mixing system. The mixing system is dispersing disk with speed of 1400 rpm. After preparing (feeding, heating, mixing) the raw materials in these two pots; then pre-treated material is sucked into the main batch pot via vacuum through pipelines.

Under the impact of high-speed rotating rotor and stator, the material is fully dispersed, emulsified, homogenized, broken to reach a well even status. Check out how emulsifying working principle in another page.

Our Vacuum Emulsifying Mixer Machine Standard

All parts that are in direct contact with raw material should be made of non-toxic, corrosion-resistant and stable, so we use 304SUS and 316L to make that.

The inner surface that is in contact with the material should be smooth; the structure should not affect the material mixing and flow; should be no dead angle to the remaining material; the surface roughness should be<0.8μm.

The surface of the agitator should be smooth, and the structure should be easy to clean without material residue. The lifting and lowering of the tank lid should be flexible, smooth, without blocking and crawling.

Water pipes, gas lines, and vacuum pipes should be firmly connected and must not leak.

The agitator and homogenizer should be adjustable in speed, flexible in rotation, and free of jamming and abnormal noise. The tank should be able to bear vacuum -0.09Mpa.

The running noise of the whole machine is < 75DB (A).

Vacuum Homogenizing Tank Operation Safety and Protection

1. Equipment must be safely earth wired

2. Tank lid won’t lift under vacuum condition

3. Agitator stops automatically when cover lift up

4. Agitator won’t work if the tank lid is not in the right place

5. Tank lid won’t lift if pinch locks not in the right place

6. If overloads of agitator, homogenizer or voltage happen, the machine will stop working.

7. During lift and lower, there is always alarming.

8. Emergency stop is available.

9. Necessary warning or tips will show on the touch screen till necessary interference is done.

10. Refill hydraulic oil pump by checking out liquid meter on it

11. Equipment should be totally shut down during maintenance.

12. Strong alkaline solution is prohibited to clean the machine

13. Keep the machine totally shut off when the machine won’t be in usage for a long time.

Tags: Vacuum Emulsifying Mixer, vacuum homogenizer, vacuum emulsifier, vacuum emulsifying machine, high shear mixer, high shear dispersing emulsifier, high speed emulsifier, high speed homogeniser

Reviews

There are no reviews yet.